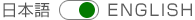

METAL FIBER CARTRIDGE

(High Filtration Area Type)

Feature

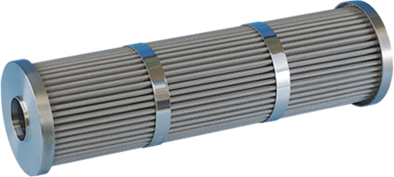

Metal Fiber ( Sintered metal fiber nonwoven fabric )

●Double filtration area by brazing process

Brazing processing has a pleat folding width higher than that of conventional products, the filtration area is doubled, and it is most suitable for high flow liquid filtration. This will reduce the number of cartridges.

●Filtration efficiency, Filtration resistance

Sintered metal fiber nonwoven fabric has a high filtering porosity of 65 to 80%, so it is a filter with low filtration resistance and high foreign matter collection ability.

●Differential pressure resistance

Because filter media is sintered, there is no sieve opening and filtration accuracy is maintained.

●Pressure resistance

Filter media is a three-layer structure and is suitable for liquid filtration with excellent pressure resistance and high viscosity.

●Chemical resistance

Alkaline and acid type chemicals are available.

●Heat-resistance

Heatproof temperature : (-190℃~)+400℃

●Reuse

It is economical because it can be washed and reused

●Configuration

Compatible common products applicable (OD φ50 ~φ70 mm, Height 250, 500, 750 mm), Can be upgraded to general filtration equipment.

Specification

Filter composition

Media:AISI316L, Support:SUS316L, End Plate:SUS316, Other:Nickel, SUS316

Filtration accuracy (Nominal)

0.8, 1, 3, 5, 10, 15, 20, 25, 30, 40μ

Filtration area (㎡)

| Nominal Length (in) | 10 |

|---|---|

| Filtration area (㎡) | 0.19 |

Pressure resistance

Forward Flow: 0.50 MPa, Reverse Flow: 0.07 Mpa

Structure

Mounting structure

H type(Flat gasket type)

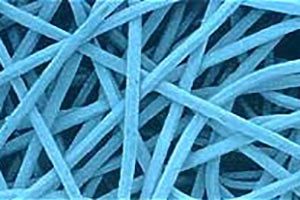

Outline drawing

NJSP

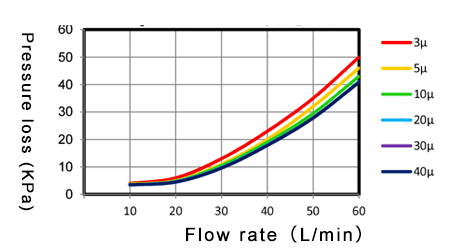

Flow characteristic

-

Water

※Including housing resistance

〈Conditions〉

(1)10 inch cartridge use

(2)Piping : 1 inch housing use

(3)water temperature : 20℃

Model

Model:NJSP-01-–

Please select and show model number.

| Grade (Nominal) |

|

|---|---|

| Gasket Materials |